In an ever-increasingly energy-conscious world, reducing our dependence on fossil fuels is always top of mind. With the advancement of technology and the implementation of new methods to replace traditional schematics with sustainable solutions, the name frequently arises is the hollow square pipe. This versatile piping solution can play a key role in creating the infrastructure for clean energy projects.

This blog post examines how they can create vital elements of alternative energy sources such as wind turbines, solar panels, and geothermal plants. We will also examine the advantages of using Hollow Square pipe cutting-edge systems rather than outdated ones like copper or steel pipes and their potential drawbacks so you can decide if they make sense for your next project.

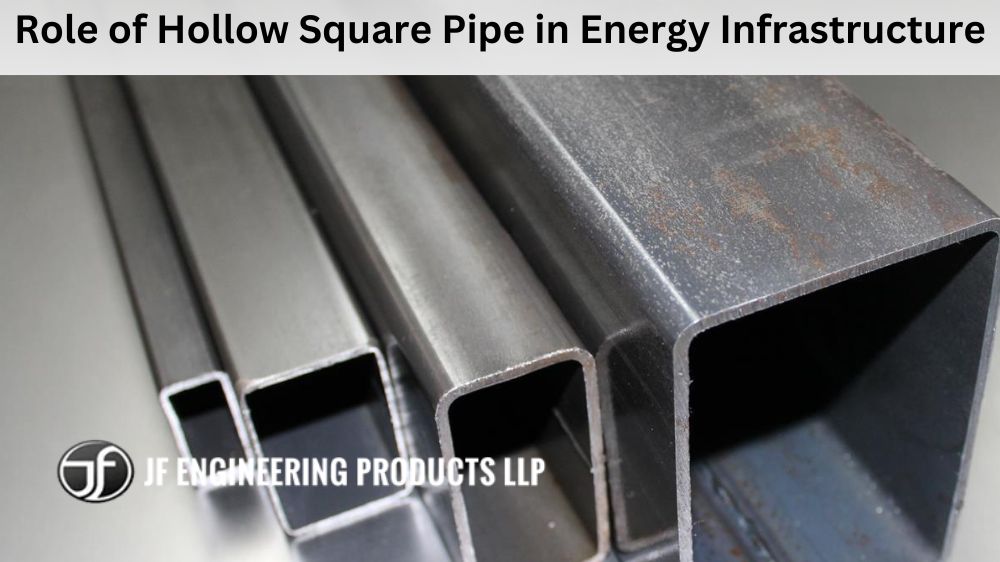

Hollow Square Pipe: An Introduction

A Hollow Square Pipe is a hollow tube manufacturers create using steel, aluminium, plastic, or other materials. It has a square cross-sectional shape with four walls, giving it more strength and rigidity than other tubing types. The hollow nature of the pipe allows air to pass through it easier for better ventilation and heat dissipation, making it ideal for use in air conditioning systems, heating applications or plumbing projects. Manufacturers can produce it in various sizes depending on its intended function, and industries often use it due to its robust construction.

Advantages of using Hollow square pipes

Durability

Hollow square pipes are constructed from steel, providing incredible sturdiness and resistance to external factors like weather and environmental changes. The material is also resistant to erosion and corrosion and doesn’t react with some of the chemicals used in the energy industry. As such, they are the preferred material for making transmission towers, rigs, and other critical energy infrastructure elements.

Easy Maintenance

In addition to their durability, they’re also easy to maintain. Their structural integrity means they only require an occasional inspection to ensure they remain in top-notch condition, even after years of exposure to harsh weather conditions. This makes them highly cost-effective and an excellent choice for long-term energy infrastructure solutions.

Versatile

The flexibility and adaptability of hollow square pipes are almost unmatched. They can be cut, shaped, and welded to fit any specific requirement—their versatile nature means that they are commonly used to build transmission towers, drill rigs, and other infrastructure elements that require a specific shape to function optimally.

High Strength-to-Weight Ratio

The hollow square pipe has a high strength-to-weight ratio, making it capable of supporting heavyweights with minimal effort. This characteristic has made them the preferred choice for structures that need light but are durable, such as transmission towers. This allows for a more efficient energy infrastructure that can carry the weight of all the necessary utilities without bogging down the tower structures.

Energy Savings

Using hollow square pipes in energy infrastructure has led to energy savings. Structures made with these pipes have a lower profile and surface area when compared to other types of pipes, and therefore, they face nearly 50% less air resistance. This translates to lower energy requirements to transfer energy and reduces the overall cost of the system.

Conclusion:

In conclusion, we cannot overstate the importance of hollow square pipes in energy infrastructure. Their durability, flexibility, and versatility make them ideal for constructing critical infrastructure components such as transmission towers, drill rigs, and other systems. Their strength-to-weight ratio offers cost benefits and leads to energy savings through reduced air resistance. Therefore, they are indispensable in constructing sustainable energy infrastructure. As we move to a greener future with clean energy and efficient infrastructure, we should remember the critical role of these often overlooked structural components in keeping the energy flowing.