Have you ever seen hollow square pipe used in any construction or engineering project? If that’s the case, people often use them when strength and stability are important. But understanding the properties and characteristics of hollow square pipe can be confusing for many unfamiliar people – but it doesn’t have to be! In this blog post, we will discuss the different types of steel alloys commonly used to create these piping systems and the strengths and weaknesses they bring. We will also review their general uses around homes and businesses, exploring how some unique features make them an excellent choice for various projects. Knowing exactly what you need from your piping will help ensure optimal results every time!

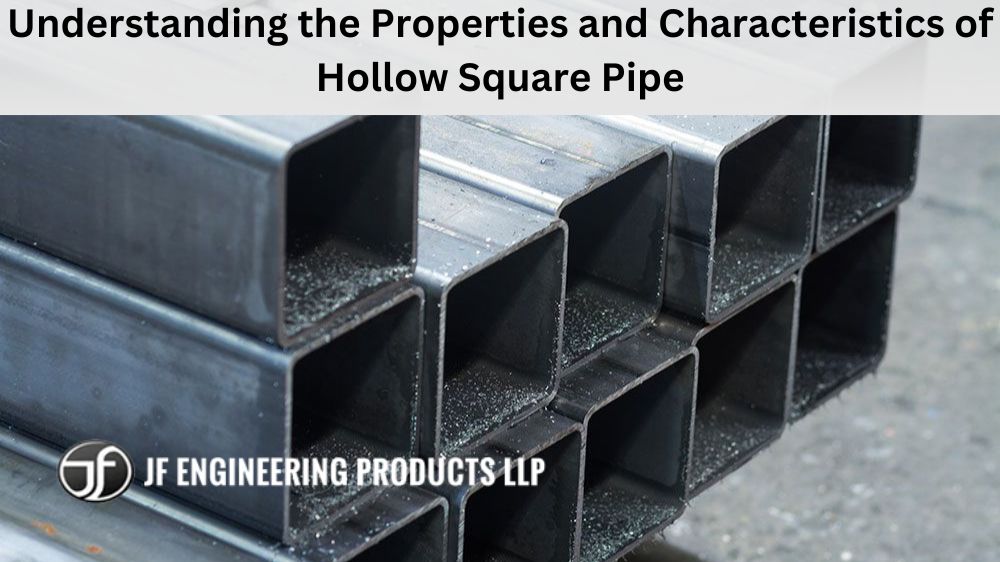

What is Hollow Square Pipe?

A Hollow square pipe is a hollow structural section typically used in welded steel frames for construction and engineering purposes. It consists of four equal-sized sides that form an angle of 90° with each other, resulting in a square shape when looked at from the side. Manufacturers make Hollow Square Pipes mostly from carbon and alloy steels like A500 GrA, A513 GrA, and ASTM A106 GrB, ensuring high strength and durability. They also come in various sizes depending on the intended purpose or application, ranging from 30mm to 600mm widths with thicknesses varying from 2mm to 40mm.

Manufacturing Process:

The manufacturing process of hollow square pipes typically involves cold or hot forming operations. In the cold-forming process, metal sheets are cut into desired shapes and sizes, then bent, formed, and welded together. The pipe is heated to its annealing temperature for hot forming operations and formed to the desired shape using a mandrel. After forming in both processes, people can correct defects such as missing welds or seams by grinding and/or welding until achieving perfect structural integrity. Finally, surface finishing gives each pipe its final appearance before shipping out for use!

Properties & Characteristics of Hollow Square Pipes

Hollow square pipes have several properties that make them ideal for use in construction. They have a high strength-to-weight ratio, so they can support heavy loads without being too heavy. This makes them ideal for structural applications like building frames and support beams. They are also resistant to deformation and can withstand high pressure and stress. Additionally, they have excellent corrosion resistance and can withstand exposure to harsh weather conditions.

Applications of Hollow Square Pipe

People use hollow square pipes in a wide variety of applications, including the construction of buildings, bridges, and other infrastructure projects. People also use them to manufacture furniture, playground equipment, and storage racks. Their aesthetic appearance makes them popular for use in architectural applications such as building facades, handrails, and fencing.

Advantages of Hollow Square Pipes

One of the biggest advantages of hollow square pipes is their versatility. You can cut and weld them to various sizes and shapes, making them suitable for various applications. They are also easy to fabricate and install, which can help lower construction costs while maintaining structural integrity. Additionally, once they reach the end of their lifespan, you can recycle hollow square pipes and repurpose them for other applications.

Conclusion:

In conclusion, hollow square pipes are a versatile and highly durable material that has become popular in the construction industry. The properties of hollow square pipes, such as their strength-to-weight ratio, ease of fabrication, and corrosion resistance, make them ideal for use in building frames, support beams, and other structural applications. They have many applications, from furniture to storage racks and playground equipment. Hollow square pipes are a reliable and cost-effective solution for constructing strong and long-lasting structures.